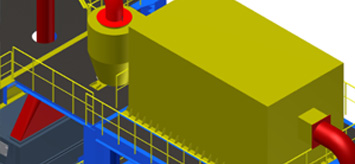

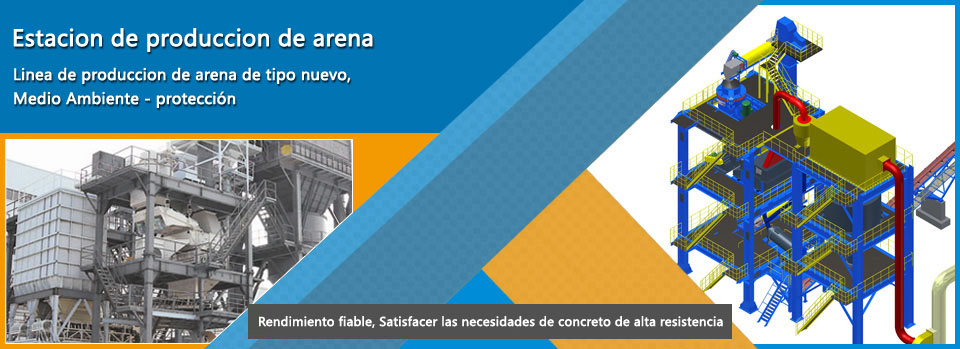

Manufactured Sand Making Station is a High Grade Manufactured Sand Production Line

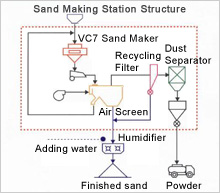

Sand making station takes VC7 series sand maker and air screen as the core, it is a closed-loop control system be composed of feeder, air blower, adjust control board, recycling filter, dust separator, auto-control fineness modulus as the core technology.

Sand making station is a dry sand making equipment, offering environmental protection manufactured sand production line with advanced technology and reliable performance for the manufacturers of cement concrete, asphalt mixture and dry mix mortar.

The top-level sand manufacturing technology of sand making station will have a deep influence on the manufactured sand production field.

Features of Manufactured Sand Making Station

1, Sand making equipment adopts VC7 series sand maker, the features of low consumption, low cost, fine particle size and stable granular composition for VC7 can meet the need of high strength concrete.

2, saving cement and coal ash, etc, decreasing the cost.

3, adopting air screen, can separate the standard product and exceeding-standard product, the grading accuracy is more accurate than before, the dust will be collected by the dust separator, the granular composition can be adjusted through adjust and control of the product. The exceeding-standard product will be sent back to be crushed again.

4, The equipment employs fully enclosed structure, the dust will not overflow out, no noise, no discharge, excellent dust-proof method.

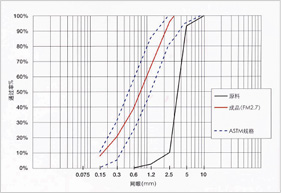

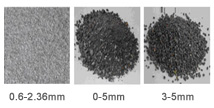

5, The production quantity with granularity between 0.6mm and 0.15mm which is difficult to produce are greatly improved through adopting newly developed VC7 series sand maker and air screen and choose the returnable closed-circuit system. The granularity is the same excellent as the natural sand (the solid volume percentage of the granularity can be up to 58-59%). Furthermore, the fineness modulus of the sand maker can be freely adjusted between 2.6-3.0, the humidifier can set proper water content which will not produce laterality to the granular composition of the product.

Dry sand making equipment can control the sand proportion according to the customers’ detailed requirements, the proportion of particle size between 2.36-0.6mm that is mostly used in the concrete and dry mortar can be increased to fully satisfy the sand requirements required by various concrete and dry mortar.

According to the statistics, It is generally acknowledged that the sand in the second region enjoys a proper particle size with better granular composition; it is the best region for concrete preparation.

The sand Making Station can keep the control of the granular composition curve in the second region, when adopting the same cement to make the concrete, the manufactured sand produced by dry sand making equipment can get greater strength.

Consultation Tel.:+86-21-5712 1166Introduction to Main Parts of Manufactured Sand Making Station

Main Machine of Crushing

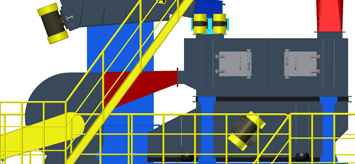

VC7 Series sand maker not only employs the same features with the vertical shaft impact crusher: low consumption, fine particle size, stable granularity, etc, its three-hole impact rotor improves its crushing performance, decreases driven force. There is less wear-out parts, durable, low cost, easy maintenance. The super hard throwing head extends its using life.

The output granularity of VC7 series sand maker is small and uniform, the soft rock can be eliminated, it employs high production rate, high crushing ratio, adopts high speed bearing with high load ability, the rotor adopts hard alloy and ceramics, etc.

Vibrating Feeder

The vibrating feeder is hanging between crusher and air screen, equipped with rubber spring, operated smoothly and steadily.

The main function of the vibrating feeder is to scatter and dilute the thickness of the layer and widen the layer width, which will help improve the air screen processing efficiency.

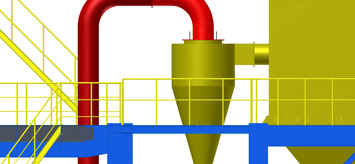

Air Screen

Through uniform feeding of the vibrating feeder, the standard product and the exceeding-standard product of the crushing materials can be separated at the same time, the rock powder will be drew away by the dust separator, The exceeding-standard product will be sent back to be crushed again. The granularity can be freely adjusted in the inner adjust and control board.

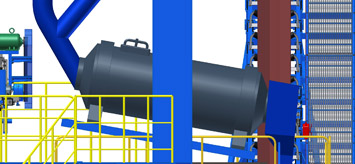

Recycling Filter

After the screening of the air screen, the part collected by the dust separator will be impacted to the adjust and control board, the heavy sand granule will drop down, return into the finished sand. The light granule that is rock flour will be drew away, which will ensure the purity of rock flour, meanwhile ensure the quality of finished sand.

Dust Separator

Adopting professional off-grid pulse dust separator to largely decrease the dust separation consumption, the dust separation rate is up to 99.9%. The complete production line adopts zero-discharge, low noise, low vibration design, equipped with large area dust separator, the rock flour produced by draught fan during the production process will be drew into the rock flour storehouse by the dust separator.

Humidifier

Newly manufactured sand humidifier can make the product enjoy certain moisture content through adding water, which ensures that the quality of the finished sand will not change during reserving and transportation process.

Electronic Control System

The electronic control system can offer all-around online and real-time inspection on equipment production status and offer chain management for safety. If any unusual circumstance appears, it can present the fault point correctly, which will help the workers to do positioning examine and maintenance, realizes correct fault positioning troubleshooting.